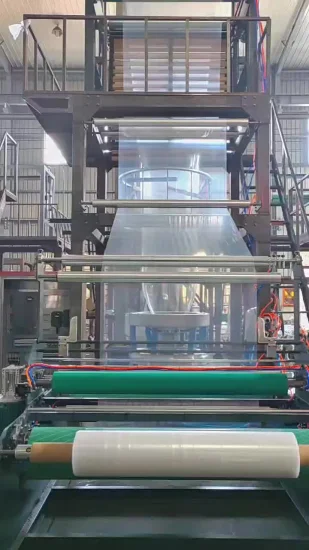

Fully Automatic High Speed Rotary Die Head and Double Winder Blown Film Biodegradable HDPE LDPE PP PE Plastic Film Blowing Extrusion Machine Price

Package size per unit product 589.80cm * 235.20cm * 239.30cm Gross weight per unit product 5200.000kg SJ-H Elevator Rota

Basic Info

| Model NO. | SJ-H |

| Type | PE Film Blowing Machine |

| Raw Material | PE |

| Maximum Folding Width of Film | 1000mm |

| Screw Diameter | 60mm |

| Automation | Automatic |

| Computerized | Computerized |

| Machine Weight | 4T |

| Certification | CE, ISO9001:2008 |

| Film Size | Can Make According to Your Demand |

| Optional Parts | Auto Loader ,Corona Treater ,Screen Changer |

| Film Thickness | 0.009-0.15mm |

| Max Extrusion Output | 35-80kg/H |

| Transport Package | Wrapping Film |

| Specification | CE |

| Trademark | Changyin |

| Origin | China |

| HS Code | 84773090 |

| Production Capacity | 2000sets/Year |

Packaging & Delivery

Package size per unit product 589.80cm * 235.20cm * 239.30cm Gross weight per unit product 5200.000kgProduct Description

SJ-H Elevator Rotary Head PE Film Blowing MachineIt is used to blow various plastic film of low density polyethylene (LDPE),high density polyethylene (HDPE) and linear low density polyethylene (LLDPE),etc.Which are widely used in packing liquid industrial product,garments,textile and printing lamination,etc.The screw and barrel of extruder are made of high quality aloy steel with optimum hardness and strong corrosion resistance after nitride treatment and precision finishing.The auxiliary machine has a plat form working table for easy operation and is equipped with double stabilizing ring.It adopts double-rolling and double-cutting coiling unit.The use of torque motor to keep proper tension and make rolling even and roll-changing easy.

Main Technical Parameters:

| Model | SJ-A45 | SJ-A50 | SJ-A55 | SJ-A60 | SJ- A65 | |||

| Suitable material | HDPE LDPE LLDPE | |||||||

| Film width(mm) | 100-500 | 300-600 | 400-800 | 500-1000 | 600-1200 | |||

| Film thickness(mm) | HD | 0.009-0.05 | 0.009-0.15 | |||||

| LD | 0.02-0.15 | 0.03-0.15 | ||||||

| Max.Extrusion output(kg/hr) | HD | 40 | 45 | 55 | 60 | 65 | ||

| LD | 45 | 50 | 60 | 65 | 70 | |||

| Extruder | ||||||||

| Screw diameter(mm) | φ45 | ф50 | ф55 | Ф60 | ф65 | |||

| Screw L/D length | 28:1/30:1 | |||||||

| Screw material | SACM-645/38CRMOALA | |||||||

| Cylinder material | SACM-645/38CRMOALA | |||||||

| Cylinder cooling | 180x2 | 250x2 | 370x2 | 370x2 | 550x2 | |||

| Driving motor (kw) | 7.5 | 11 | 15 | 18.5 | 22 | |||

| Temperature control | 3 | 3 | 3 | 3 | 4 | |||

| Average power-consume(kw) | 10 | 12 | 18 | 22 | 30 | |||

| Type of die | ||||||||

| Die size | HD | ф60/80 | ф80/100 | ф100/120 | ф100/120 | ф100/150 | ||

| LD | ф100/120 | ф120/150 | ф180/200 | Ф200/220 | ф220/ 250 | |||

| Temperature control | 3 | |||||||

| Air ring | 1 | |||||||

| Air blower(kw) | 1.5 | 2.2 | 3 | 3 | 4 | |||

| Center steady stick | 1 | |||||||

| Take-up unit | ||||||||

| Roller width(mm) | ф165×600 | ф165×700 | ф165×900 | ф165×1100 | ф165×1300 | |||

| Height adjustable type | 800mm | |||||||

| Take-up speed(m/min) | 10-100 | 10-100 | 10-80 | 10-80 | 10-80 | |||

| Take-up motor(kw) | 0.75 | 1.1 | 1.1 | 1.1 | 1.5 | |||

| Winding unit | ||||||||

| Type | Surface friction type | |||||||

| Winding motor(N.m) | 10 | 10 | 10 | 16 | 16 | |||

| Winding speed(m/min) | 10-100 | 10-100 | 10-80 | 10-80 | 10-80 | |||

| Cover dimension(m) | 5.0×2.0×4.1 | 5.0×2.2×4.5 | 5.5×2.5×5.2 | 5.6×2.8×6.0 | 5.8×2.8×6.3 | |||

Optional Equipment:

1.Auto Loader2.Corona Treater3.Rotary Die Head4.Air Compreessor5.Mechanics Screen Changer6.Double Winder7.Air Shaft8.Cutter

Send to us