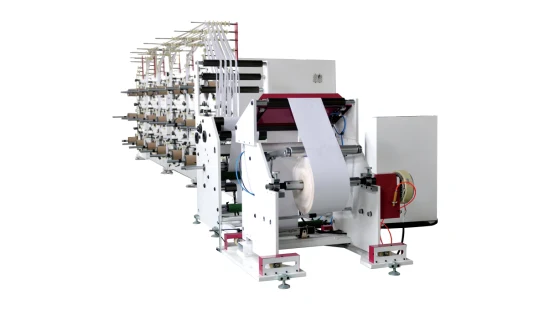

High-Speed Label Sticker, Labelstock, Labels Slitting Machine

Basic Info

| Model NO. | HCH2-1300/1700 |

| After-sales Service | 24 Hours Feedback Online . |

| Warranty | 1 Year |

| Application | Mechinery&Hardware |

| Type | High-Speed Slitting Machine |

| Work Method | Round Knife Cutting |

| Structure | Cutting Part |

| Packaging | Wooden Pallet |

| Classification | Slitting Machine for Paper Sticker |

| Applicable Process | Process Materials |

| Suitable Substrates | Adhesive Label, Paper, Film, Tape, Aluminum Foil |

| Packaging Material | Wood |

| Speed | 200 M/Min |

| Precision | 0.03 mm |

| Motor | Servo Motor |

| Certification | Ce, TUV |

| Machine Body Thickness | 45mm |

| Inverter | Delta (Taiwan) |

| Ultrasonic Rectification | Pausource (Taiwan) |

| Auto. Length Counter | Omron (Japan) |

| Pneumatic Element | Airtac (Taiwan) |

| Knife | Knipia (Korea) |

| Transport Package | Pallet |

| Specification | 2700*3050*1580mm |

| Trademark | LOYAL |

| Origin | China |

| HS Code | 8441100000 |

| Production Capacity | 100 |

Product Description

High-Speed Paper Sticker Adhesive Label Slitter Rewinder Machine Videohttps://youtu.be/upSwExmbCMcTechnical parameter

| Model | HCH2-650 | HCH2-1300 | HCH2-1700 |

| Slitting effective width | 30-650mm | 30-1300mm | 30-1700mm |

| Slitting speed | 300m/min | 300m/min | 300m/min |

| Unwinding roll diameter | φ1000mm | φ1000mm | φ1000mm |

| Rewinding roll diameter | 2*φ600mm | 2*φ600mm | 2*φ600mm |

| Main motor power | 4kw | 5.5kw | 7.5kw |

| Rewinding motor power | 5.5kw | 7.5kw | 11kw |

| Total power | 11kw | 13kw | 21kw |

| Precision | ±0.03mm | ±0.03mm | ±0.03mm |

| Machine weight | 2000kg | 3500kg | 4000kg |

| Machine overall dimension | 2700*2000*1580mm | 2700*2650*1580mm | 2800*3150*1600mm |

Use

This type high speed slitting machine is the ideal processing machine for high demand of speed and precision of label stikcer ,paper ,PET film etc optical film and electric film slitting and rewinding .

Characteristic

This roller material slitting machine is a high speed, high precision equipment. It plus PLC based on standard features,which can control the whole machine operation via human-machine interface, the tension was calculated automatically by the PLC addition and subtraction. Automatic correction, precision and even slitting.

Advantage

1. SIEMENS PLC control, Touch screen on human machine interface with high resolution colors and easy operator controls.2. Heavy machine body processed by CNC: ensure machine running in high speed stably and long time lifetime.3. Automatic shaftless adopted to improve the efficiency and assure the operator safety.4. Shaftless loading control by hydraulic system, more powerful and strength than pneumatic cylinder control.5. Main motor and rewinder motor adopted servo motor + JAPAN YASKAWA inverter control.6. Unwinding tension and rewinding tension controlled by SIMENS PLC and JAPAN SMC proportional valves, automatic tension control, keep tension stable. 7. Pausource web guide system, adopted ultrasonic inspection, servo motor drive, ensure the material running stable and precision of align.8. High quality KOREAN circular blade adopted, SKH-2 material ensure the lifetime and also the slitting accuracy.9. Automatic counter wheel KOREA AUTONIC adopted, ensure higher precision for meter counting.10. Synchronous belt transmission, low noise, running more steady.11. Outside splicing table, which is more convenient for worker to operate and increase the productivity.12. All the guide roll are processed by dynamic balance treatment, which make sure the machine can run in high speed stably.13. Rubber roller adopted polyurethane material, more wear-resisting and own longer lifetime.14. Aluminum roller adopted harden oxidation treatment, have the characteristic of high hardness and surface is more smooth, anti-scratch. 15. Friction shaft, each unit's tension can be compensated automatically and ensure the slitting effect is more smooth and even.16. Auto blade set as option. 17. Auto push can be selected as option.

Main configuration

| PLC | SIEMENS (GERMANY) |

| TOUCH SCREEN | WEINVIEW (TAIWAN) |

| MAIN MOTOR | SERVO MOTOR |

| INVERTER | DELTA (TAIWAN) |

| MAIN PNEUMATIC ELEMENT | AIRTAC (TAIWAN) |

| MAIN BEARING | NSK (JAPAN) |

| PROPORTIONAL VALVES | SMC (JAPAN) |

| WEB GUIDE(ULTRASONIC RECTIFICATION) | PAUSOURCE (TAIWAN) |

| AUTOMATIC METER COUNTER(DIGITAL) | OMRON (JAPAN) |

| KNIFE | KNIPIA (KOREA) |

| LOW-VOLTAGE ELECTRIC | CHINT or SCHNEIDER |

| STEEL PLATE THICKNESS(MACHINE BODY) | 45mm |

Application

Our Service

How about your payment term? What kind of payment term you can accept? As usual, the payment term is TT,30% deposit, the balance after machine testing and before delivery; also, the LC at sight is acceptable for us.Under this difficult time, If I buy your machine, how to install and operate the machine? Our machine designed have considered this point, so our machine sending is as whole set, no need installs anymore.A video will be taking for you for the power supply cable connection.The operation video took as English subtitle to you for clear guiding.How about your guarantee? 12 months guarantee, lifelong time technic maintenance and support24 hours feedback when receive the client writing militance proposal. How about the spare parts? Spare parts qty is sufficient for you with machine together;The price of spare parts exceeding the guarantee would be at lowest ex-factory price for you

Running in client's factory

Contact us without hesitation! We are willing to send you in greater detail!