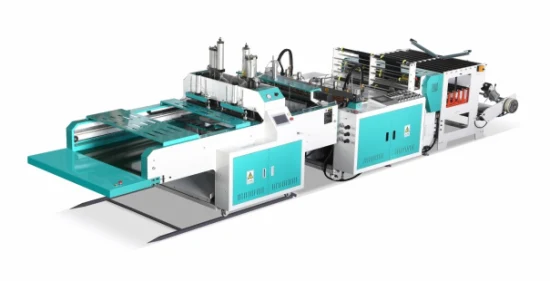

Automatic High Speed Vest Plastic Non-Woven Bag Making Machine

Basic Info

| Model NO. | CZ500X2 |

| Speed | High |

| Continuous-Rolled | Yes |

| Sealing & Cutting | Heat-Sealing Heat-Cutting |

| Layer | Single |

| Machine Type | Bag Forming Machine |

| Computerized | Computerized |

| Type | Plastic Bag Making Machine |

| Model | 500×2 |

| Bag Making Speed | 100-380PCS/Min×2 |

| The Machine Weighs | 2700kg |

| The Bag-Making Thickness | 0.01-0.05mm |

| Transport Package | Plastic Film/Bubble Film |

| Specification | L6800XW1700XH1800mm |

| Trademark | CHAOSHUN |

| Origin | China |

| HS Code | 8441200000 |

Product Description

This machine with HDPE, LDPE tube film as raw materials can produce printing, color, vest bag, using PLC control, stepper motor fixed length, LCD touch screen real-time display, from the feeding, cover, cutting, punching, conveying one-time completion, high degree of automation, good economic benefits.

1. This machine is a special machine for vest bag heat sealing. It can automatically punch double lines to increase production and save manpower.

2. This machine is double track, double production line, double printing bag, double servomotor.

3. Electric eye induction tracking, precise printing pattern, automatic stop warning when the electric eye fails.

4. Main motor inverter control, simple operation, reduce power consumption.

5. Automatic stop device without material.

6. The machine can reach the set number of sheets, punching machine immediately clamp the bag, do not need to stop, can continue to feed.

7. The newly designed sealing knife structure, when the sealing knife needs to be cleaned, the sealing knife can be turned over 180 degrees to fix to clean, safe and reliable, maintenance is easier.

8. The bag is neat and sealed firmly.

9. Using gas-liquid booster cylinder punching machine, low noise, small gas consumption.

Main technical parameters

| configuration parameter | ||

| Model | 500 x 2 | |

| Maximum bag-making length | 280-650mm×2 | |

| Maximum bag-making width | 180-430mm×2 | |

| Bag making speed | 100-380pcs/min×2 | |

| The bag-making thickness | 0.01-0.05mm | |

| Total power | 16kw | |

| The machine weighs | 2700kg | |

| Overall dimensions | L6800×W1700×H1800mm | |

| The air pressure | 10HP | |

| Main frame | Iron plate | |

| Feed control system | Analog control | |

| Cutter heating method | Current heating | |

| Punching frame | Steel plate | |

| Discharge method | Lever (independent discharge) | |

| Discharge brake | Magnetic powder 5 kg | |

Detailed Photos

Our Advantages

The company specializes in the production of various types of film blowing machine die head, die head plated with hard chromium, its structure is spiral mand-shaft, uniform discharge, smooth. The blowing film die head is composed of a die body (die core, die cylinder, die ring) and a heater (heating ring). The first selection, is to choose the corresponding material. The second step is forging, forging the material into the mold parts of the rough embryo, the molecular structure of the forged embryo is more dense. The third is to carry out lathe processing, according to the design drawings of the die head car out of the die head, in the lathe processing, as far as possible with high precision lathe, and skilled lathe master car. The fourth is polishing, polishing the runner part of the car mold, the better the finish, the better the blown film, the more no silk road. The fifth is chromium plating. The runner part of the polished mold is plated with chromium, so that the runner part has a layer of hard chromium, which increases the wear resistance and corrosion resistance of the die head and then polishing, which can make the mold not easy to damage and not easy to produce residual coke. Finally, the parts of the mold are installed and the heating ring is put on. Die head structure according to the characteristics of LDPE, HDPE, LLDPE three kinds of polyethylene, after many comparative tests for selecting and shaping, has the advantages of large internal pressure, stable and uniform extrusion, film strength performance is good, no crack and the extruder of this unit good match. At the same time changing the ratio of three kinds of polyethylene and mixed material, recycled material blowing film production can be done without replacing the die head on the method, only one; Take the method up, to the best. Zhengyu company always adhere to the principle of "people-oriented", in strict accordance with the modern enterprise system and standard management, actively create the best corporate culture, constantly absorb high-quality talents from all sides to join, inclusive, learn from others, our company has made great achievements, set up a good image in the industry, greatly enhance the brand competitiveness. Our company provides non-standard design, production and commissioning one-stop service, welcome customers with material test, inspection and ordering. Sincerely welcome new and old customers sincere cooperation, super shun will, as always, forge ahead, in order to build China's drying enterprise and forever forward, in the new century with you to create the first!

https://chaoshunmachine.en.made-in-china.com/contact-info.html