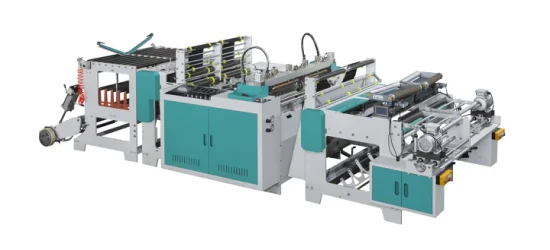

Fully Automatic High Speed Flat Handle and Paper Twisted Handle Switching Kraft Kfc Paper Shopping Gift Food Handbag Bag Making Machine

CE Good quality Paper Bag Machine SBR180 Technical parameter: Width of Paper 286-600mm Length of Bag 190-370mm Width of

Basic Info

| Model NO. | SBR180 |

| Size and Shape | 4100×1900×1600 |

| Long | 190-370 |

| Weight | 3600 |

| Material | Paper |

| Usage | Shopping Bag, Garment Bag, Leisure Food Bag, Bread Bags, Airsickness Bag, Fruit Bag |

| Paper Roll Unwinding | Automatic Tension Control |

| Gluing Equipment | Zator From Italian |

| Correction System | Selectra From Italian ( St) |

| Servo Motor | Mitsubishi From Japan |

| Photoelectric Tracking System | Sick From Germany |

| Transport Package | Wooden Box |

| Specification | ISO/CE |

| Trademark | HONGYING |

| Origin | Wenzhou China |

| HS Code | 8441200000 |

| Production Capacity | 100sets /Month |

Product Description

CE Good quality Paper Bag Machine SBR180

Technical parameter:

Width of Paper 286-600mm

Length of Bag 190-370mm

Width of Paper Bag 80-180mm

Width of Bag Bottom 50-100mm

Paper weight 45-120gsm

Max. Diameter of Paper Roll 1400mm

Internal Diameter of Roll Core 76mm

Max. Speed 200PCS/min

Total Power 10Kw

Weight of Machine approx. 4000 kg

Overall Dimension L9200mm x W1600mm xH1700mm

Structure features

1. Adjustable roll to square bottom bag making machine

2. Introduce In-touch screen human-machine interface, easy for correction and fine adjustment. Alarm and working status can be displayed in screen on-line, easy for operation and maintenance.

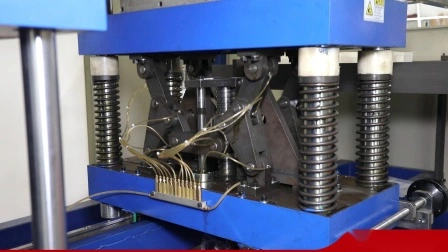

3. Equipped with Mitsubishi PLC for centralized control system and SICK photocell for correction, tracking the printed material accurately, minimize the adjustment and preset time, increase the production efficiency.

4. Human oriented security protection, whole housing design, ensure the safety of operator.

5. Physiosis roller hydraulic material loading system with chuck, hydraulic up/down system

6. Automatic constant tension control for unwinding, EPC web guider system, motor for material feeding with inverter, minimize the adjustment time for web alignment.

7. High speed oriented design ensure successful of production: Within the suitable paper range, production capacity can reach 150~200pcs/min, even higher, which increases the unit production capacity and gets higher profit.

8. Original SCHNEIDER electric system, ensure better stability and reliability; Perfect after sale service, trouble free for customer.

Send to us